WHAT IS POLYETHYLENE?

Polyethylene is a high density type of plastic. Comparing to other polyethylene materials, it is much more solid and stronger. Polyethylene’s density is less than water. It can be produced using moulding technology or with extrusion method. It is possible to merge the plates by special welding methods and it also can be processed on workbenches. It is very hard to merge them using and adhesive material. The appearence of polyethylene is mat, opaque and looks like wax. It is also a very clean material, it can contact with food without spoiling it.

Polyethylene boats have been manufactured since the beginning of 2000’s all over the wworld. Due to idiosyncratic of polyethylene, these boats give very good and high performance as especially workboats. Beside performance; polyethylene boats provide high safety sails on all kinds of sea conditions.

PARTICULARS OF POLYETHYLENE

DURABILITY

It is resistant to material aging. Lifetime of polyethylene is calculated as at least 50 years, but the performances prove that it is much higher in reality.

LIGHT AND EASY TO PROCESS

Carrying polyethylene plates are so easy that it gives an important advantage at production, comparing to heavier materials, like steel.

FLEXIBILITY AND ENDURANCE

Flexibility of polyethylene prevents deformity of material and cracking on surface. It is very resistant to collision damages and also resistant to tension cracks and crack expansion.

ADAPTABILITY

Polyethylene is not fragile, even at the low temperatures. It is resistant to freezing and also does not effect from freezing of the liquid it is in.

GOOD WELDING FEATURES

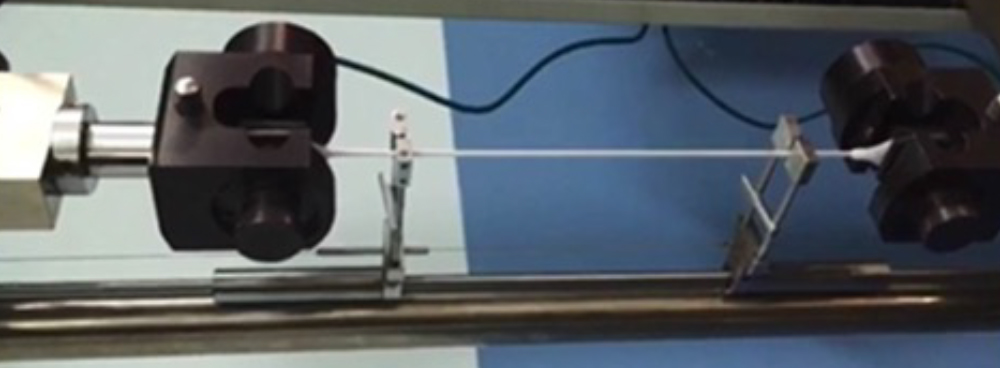

The tests show that, welding lines are much stronger than jointless pipe zones, especially the welding points merged with electro fusion and butt-welding, these points are extremely durable.

RESISTANCE TO CHEMICAL EFFECTS

Polyethylene material is highly resistant to chemical corrosive products. In different work areas, polyethylene is used for production of chemical tanks or acid tanks.

EASY CLEANING

Polyethylene does not get dirty easily, it does not contain toxic matter and very easy to clean.

WHY POLYETHYLENE BOATS?

WEIGHT ADVANTAGE

Polyethylene’s density is between 0,96 g/cm3. This means it is 1/8 times lighter than steel and 1/3 times lighter than aluminium. Therefore polyethylene boats can easily reach required speeds with low powers.

ELASTICITY

Polyethylene is a very convenient material for sea conditions due to its elasticity, it is almost impossible to crack the material or welding unless colliding to rocks with more than 25 kn speed.

Polyethylene is so elastic that it is always impossible to crack it

RESISTANCE TO CORROSION AND SEA CREATURES

Polyethylene is not affected by seawater. Therefore polyethylene boats do not need to be painted. As there is no corrosion; polyethylene boats do not need to be maintained. Polyethylene plates do not need to be renewed at all. Therefore it is possible to utilize polyethylene boats being in service for many years without maintenance.

Polyethylene plates are manufactured with different colors originally

HIGH TENSION RESISTANCE AND ABILITY TO ABSORB IMPACT

Thanks to its high tension resistance, boat’s shell plates can easily absorb any impact and take minimum damage from impacts like collision or grounding. In case of any damage, it can be repaired very easily. Polyethylene is an ideal material for boats which will work in shallow water or seashore.

REPAIRING & EASY WORKMANSHIP & MODIFICATION

It is possible to make local repairs for damaged parts of a polyethylene boat. Any repair or welding can be done easily and fast. Polyethylene boats are constructed with cnc cutting and welding method, and can be shaped easily. As the production method is not moulding, it is always very easy to make modifications on polyethylene boats.

LOW INVEST AND RUNNING COST

Being very light; polyethylene boats do not need high powers and consume very less amount of fuel. Being corrosion-free; polyethylene boats do not need to be paid for maintenance during whole lifetime. Being very elastic; polyethylene boats are always in service.

HIGH MANOUVERABILITY

Polyethylene boats are very light and adaptable to all kinds of propulsion systems. This gives polyethylene boats an important advantage for manouvering especially at narrow and shallow seas.

SECURITY

Polyethylene boats are built as double hull at bottom. The space between two hulls is filled with polistren foam. Therefore it is amost impossible to scuttle polyethylene boats.

ENVIRONMENT FRIENDLY

At production, carbon emission values of polyethylene is 5 times lower than aluminium and GRP. Also unlike them, polyethylene can be recycled %100. Additionally; as polyethylene does not need to be painted; there is no paint molecule mixed into the sea.

Polyethylene %100 recycled.

POLYETHYLENE BOAT TYPES

It is possible to build crew transfer boat, pilot boat, agency boat, service boat, passenger boat, sea taxi, police boat, search boat, navy boat, ambulance boat, firefighting boat, waste cleaning boat, fishing boat, diving boat, tug boat etc. with polyethylene. It is also possible to install different types of propulsion systems, such as inner or outer engines, water jet, surface propeller and conventionel shaft-propeller.

SOME OF THE MATERIAL PROPERTIES OF POLYETHYLENE

| Density (g/cm³) | 0,96 |

| Tensile Modulus of Elasticity (Mpa) | 1100 |

| Yield Stress (Mpa) | 23 |

| Elongation at Yield (%) | 9 |

| Elongation at Break (%) | ≥300 |

| Impact Strength (KJ/m²) | Without break (Kırılmaz) |

| Notched Impact Strength (KJ/m²) | 30 |

| Ball Indentation Hardness (Mpa) | 40 |

| Shore Hardness D (15 s) | 65 |

| Fire Behaviour | B2 |

| Dielectric Strength (kV/mm) | 47 |

| Temperature Range (°C) | -50 to +80 |

| Physiological Safety in Accordance With EU | Yes |

| Thermal Conductivity (W/m*K) | 0,38 |